Pump is a mechanical device which converts mechanical energy into hydraulic energy. Same in case of reciprocating pump, it is used to increase the energy of flowing liquid. Pump increase the pressure energy of liquid which is then converted into potential energy when liquid is lifted from a lower level to a higher level.

Reciprocating pump is a type of positive displacement pump i.e. priming of pump is not required. Positive displacement pump means pump sucks liquids and then pushed due to the thrust exerted on it by moving member, which helps in lifting the liquid to the desired height and location. Reciprocating pumps may have one or more than one chambers which are alternatively filled with the liquids after that it pumps the liquid by some thrust force then empty again this process continuously repeated and water delivers at desired location. Reciprocating pumps are used to supply low discharge at high head.

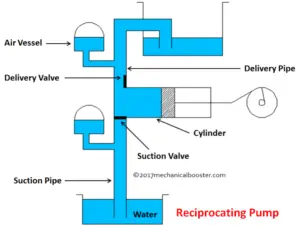

Reciprocating Pump:

Construction:

A reciprocating pump has following parts.

1. Cylinder and piston: Reciprocating pump consists of a piston and cylinder arrangement. Piston moves to and fro in the cylinder i.e. piston reciprocates inside the cylinder that’s why it is known as reciprocating pump. Piston and cylinder is generally made up of cast iron or steel alloy.

2. Crank and connecting rod: Piston is connected to crank by means of connecting rod. Crank is driven by some external source like some engines or electric motor. Crank rotates at uniform speed. The connecting rod attached with piston and crank; which converts rotary motion of crank into reciprocation motion of piston i.e. piston moves in to and fro motion when crank is rotating.

3.Suction pipe: Suction pipe is connected to cylinder and source of water. It transfers water from source to cylinder.

4. Delivery pipe: Delivery pipe attached with cylinder to delivery end. Water is delivered through this delivery pipe.

5. Suction and delivery valves: Suction and delivery both the pipes are provided with one way or non returning suction and delivery valves. These valves permits entry and exit of water in one direction only i.e. suction valves allows the liquid to entry into the cylinder only and delivery valve permits only delivery/ discharge of liquid from the cylinder. We can also call them input and output valves.

6. Air vessels: Air vessels mostly use in case of single acting reciprocating pump. It is used to obtain continuous supply of liquid at a uniform rate from a single acting pump and it helps to maintain uniform rate of flow of liquid in both cases i.e. suction and delivery. Air vessel is a close chamber generally made up of cast iron and having an opening at its base through which the liquid flow out from the vessel. In air vessel top portion is filled with compressed air and at bottom some amount of liquid is present.

Working:

Working of reciprocating pump is very simple. It works like a reciprocating engine. When crank starts rotates from 0 degree to 180 degree then the piston moves from extremely inward position to outward position, this time a partial vacuum is created in the cylinder i.e. pressure in the cylinder is slightly less than the atmospheric pressure. Due to this suction generates into the suction pipe this time suction valve is open and delivery valve is closed. The liquid comes into the cylinder fill into the cylinder. This is known as suction stroke. In starting of this stroke crank angle is 0 degree and at the end of this stroke crank angle is 180 degree. This time suction valve is closed and delivery valve is just about to open.

When crank rotates inward from 180 degree to 360 degree the piston moves inward from outward. This movement causes the pressure increase into the cylinder above the atmospheric pressure. This time suction valves close and delivery valves opens. The liquid forcefully pressed and delivered at required portion or height. This is known as delivery stroke. In both the strokes a complete revolution of crank is done. This process is continuously repeated and the delivery of liquid is done continuously.

Types of Reciprocating pump:

Reciprocating pump may be classified in two ways

According to the contact of liquid with piston:

It can be one side or both side i.e. single acting pump and double acting pump.

According to number of cylinders provides:

- Single cylinder pump

- Double cylinder pump

- Triple cylinder pump

- Duplex double acting pump

- Quintuplex pump

According to the contact of liquid with piston:

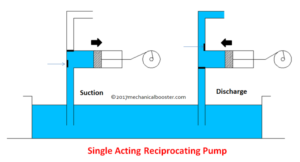

Single acting pump: As name suggest if the liquid is contact with the piston in one side and having only one suction and one delivery pipe then it is known as single acting pump. In single acting pump one crank revolution have only two strokes i.e. one is suction and second is delivery stroke.

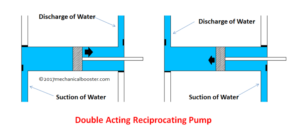

Double acting pump: In this type water comes in contact with the piston on both the sides and having two suction and two delivery pipes with attached valves. In double acting pump in each stroke from one side suction and other side delivery takes place. In this manner double acting pump has two suctions and two delivery stroke in one complete revolution of the crank.

According to the number of cylinders provided:

Generally when a reciprocating pump have more than one cylinder then it is known as multi cylinder pump but some cases of different number of cylinders are as follow.

1. Single cylinder pump: As name suggests a single cylinder pump have only one cylinder, this can be single acting or may be double acting as per the requirement.

2. Double cylinder pump: A double cylinder pump has two possibilities i.e. having two cylinders with two separate pistons and having two cylinders in line but with single piston.

In first case when two cylinders with two separate pistons, each equipped with one suction and delivery pipe with attached valves both the piston moves in cylinder at same time.

In second case where one piston is for two cylinders have one suction pipe and one delivery pipe. In this arrangement when piston moves suction is done though one cylinder and delivery of liquid is takes place by second cylinder. The working of double acting pump is similar to double acting single cylinder pump. A double cylinder pump is also known as two throw pump.

1. Triple cylinder pump: This is also known as three throw pump. In this type three cylinder having three separate pistons works together, all the three cylinders have separate delivery and suction pipes with appropriate valves. All three pistons moves together from a crank set angle of 120 degree.

2. Duplex cylinder pump: This is also known as four throw pump. In this case two double acting single cylinder pumps or may be two double acting double cylinder pumps are arranged. This arrangement is works with two cranks, each piston cylinder arrangement have separate crank with a set of 90 degree angles.

3. Quintuplex pump: It is also known as five throw pump. It has five single acting cylinders driven by cranks at 72 degree. The entire cylinder has their separate suction and delivery pipes with appropriate valves.

Advantages:

- The main advantage of reciprocating pump is there is no requirement of priming in it as it is positive displacement pump.

- It can be used for supply liquid at high pressure.

- It is used to deliver the liquid at high heads.

- Reciprocating pumps are highly durable i.e. can be use in adverse conditions like in corrosive applications.

- It can works for air as well as with liquids.

Disadvantages:

- The major drawback of this pump is its lower efficiency as compared to centrifugal pumps.

- Reciprocating pumps have low discharge.

- These pumps require high maintenance sometimes wear and tears happen in it, in adverse operating conditions.

- Reciprocating pumps are heavy and large in size.

Applications:

- Reciprocating pump used in water jet cutting, where high pressurized liquid is required at high velocity.

- It is widely used in oil and gas industries, power plants, water treatment plants and sugar industries.

- These pumps use where low discharge is required at high presser.

- Reciprocating pump is used to fill air into the tires of bike or bicycles.

- The most important and common use of reciprocating pump as hand pump.

This is all about reciprocating pump working and its types. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more informative article. Thanks for reading it.

Image Source: http://www.mechanicalbooster.com/2017/08/reciprocating-pump.html