Septic tank pump is an essential part of the plumbing system that is used for the cleaning process in the septic tank. It is a pump that spells out wastewater from the main tank to another location, usually the drain field. Once the chamber is full, a float switch turns on the septic pump.

Mostly, some households are far from the main sewer lines, prompting the construction of a septic tank. It is usually not that costly, but with everyday bathrooms, kitchens, and household laundry, the septic is bound to get full with time.

This is where the Septic tank pump comes in to help you pump out excess waste in the septic and dispel it to your drain field. Let’s look at how the septic tank pump works, how it is installed, and its principle.

Septic Tank Pump:

First of all before look about septic tank pump, we should know about septic tank. lets start the discussion.

What Is a Septic Tank?

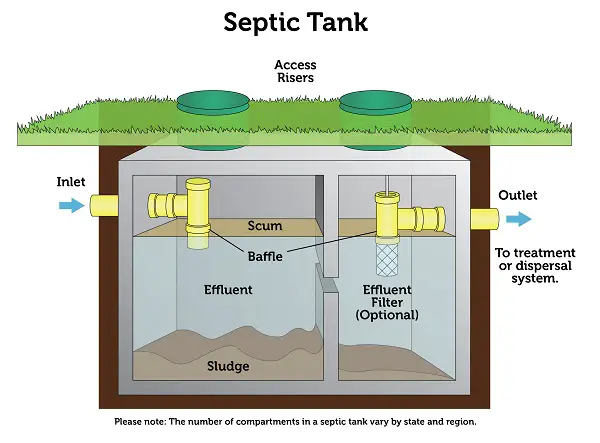

A septic tank is an underground holding container that purifies wastewater through a process called biological decomposition and drainage. Septic tanks use the natural processes of decomposition and evaporation to treat wastewater from bathrooms, kitchens, and laundry rooms.

A septic tank has a relatively simple design of an underground watertight container made of plastic, concrete, or fiberglass. The T-shape compartment in the septic tank prevents sludge and scum from leaving from traveling into the drain field area.

How a Septic Tank Works?

Water from your kitchen, bathroom, etc., runs through one main drainage pipe leading to a septic tank. When underground, the septic tank starts the process of holding wastewater, it needs to hold this long enough so that solid waste settles down at the bottom while oil and grease float on top.

After everything has settled, the effluent, which is the wastewater, will then exit the tank into the drain field. The wastewater is filtered through the soil once it is discharged into the field through the soil.

The next step is for the soil to treat and then dispense wastewater, after which it discharges it into the groundwater. Finally, the wastewater is percolated into the soil, where harmful coliform viruses, bacteria, and nutrients are naturally removed.

You can also watch the following video for better understanding of septic tank working.

Constructing of a Septic Tank:

Before building your own septic system, contact the local health department and county government offices to determine whether this is acceptable in your area. Make sure you understand any permits and inspection requirements and get the paperwork before beginning work. Follow local septic system regulations closely during construction to avoid having to remake your entire system later on.

Here is a procedure of how to build a septic tank.

Plan Your Site

Determine the best place you will put the septic tank and the drain field, and follow any requirements by your local laws, like the soil testing and how deep your septic tank should reach. Remember that your septic tank should be able to fit into the dug hole, so ensure that you have your measurements right to avoid repeat work.

Knowing the right septic tank to purchase takes about 75 gallons of septic tank space per person per day. For instance, a family of five would need 75 x 5 = 375 gallons; this size may be necessary for larger families or households with more than one bathroom.

Plan to store at least 150 gallons of water daily to be safe. If possible, use a 1,000-gallon tank so your sludge won’t have to be pumped out as often (as it would with a smaller tank).

Preparation:

To dig the pit for your septic tank, use a backhoe or shovel, or hire a professional excavating company. If you choose to do it yourself by hand rather than spend more money on hiring outside help, be prepared for some hard work! Talk with your installer or a structural engineer to determine how big your hole will need to be. You will also need to dig an area for a pipe that will be running from the house to the tank, depending on the measurement agreed upon by your expert.

To dispose of liquid waste, you must run a pipe from the tank to the leach area.

Connecting the drain pipes can either be done before or after the tank has been placed on the ground.

Depending on the county’s survey and whether or not you live in an area with poor drainage, and may need to be brought into your yard so that the septic tank doesn’t become water-logged.

You should remember to place the drain field at least 10 feet away from your residence and any body of water, such as a pond or river. Dig trenches for two sections that are 50 feet long and four sections that are 25 feet long (or some combination thereof).

The trenches should be 3–4 feet deep and 3 feet wide. The trench also needs a slight downward slope so that the waste can drain out of the pipe into it. After digging, fill each trench with 1 foot of gravel or “drain rock.”

Install the Tank:

You can now install the top of the tank. To prevent gases from forming in the tank, use a concrete slab. Place a galvanized pipe (at least 2 inches in diameter) on top of it. The longer, the better because it allows more time for escaping vapors to dissipate into the air. Note: when operating properly, septic tanks should not smell.

The top of the tank has 2 large manholes, which are normally sealed with grout to make them air-tight. Manholes allow someone to enter and exit a tank should maintenance be needed, making sure that you can access both inlet and outlet pipes for clearing blockages.

Manhole covers are designed to seal with horizontal surfaces, but in some places, you will find that contractors may make the manholes and their covers fit together with a tapered joint.

Tapered joints are difficult to make and so difficult to seal. Instead, use flat surfaces that can be more easily fastened and sealed. Also, ensure the manhole covers have steel handles, so they can be lifted by hand if necessary.

Connections and Finishing Touches:

After you have prepared your site and laid the septic tank down, connect together all of its components. Attach a perforated pipe to one that comes out from inside the tank.

Place additional gravel on top of the perforated pipe to keep the dirt from filtering down into it, and place a thin sheet of filter fabric over this layer. Then cover everything with soil that was removed during excavation.

Principles of a Septic Tank Pump:

A septic tank pump works similarly to a groundwater sump pump, but instead of pumping rainwater out of the home, it operates by raising sewage from within the septic tank and shunting it into the main drain field. All plumbing systems that include sinks, tubes, and toilets located below the level of the main sewer line must be equipped with a pump to raise wastewater to where it can flow down and out properly.

A septic tank pump sits in a septic tank, which is cut and dug into the ground below grade. The septic tank accumulates and holds around 30 gallons of waste for an average-sized home.

The drain lines in the basement slope into the side of the sump basin, and when the wastewater level in the septic tank reaches a certain height, a float switch on the septic tank pump starts the pump.

The wastewater then flows into a drain field and is dispersed into the soil. Once the level of water in the septic tank goes down, a float drops and switches off the pump until the septic fills again.

Types of Septic Tanks Pumps:

Grinder Pumps:

Sewage ejector pumps, more commonly known as grinder pumps, are installed in basements or yards of homes to remove sewage. If your home’s plumbing drainage system is lower than that of your septic tank or drain field, a grinder pump will usually be necessary to keep the entire system in working order.

As the name goes, a grinder pump grinds sewage into a finely ground slurry and pumps it out to your septic tank.

Home and septic systems may be of the same grade, but a grinder pump may still be required to achieve an ideal sewage drainage rate of 2 feet per second in such situations.

Effluent Pumps:

Effluent pumps are installed in the last chamber of a septic system and move sewage to your drain field. These pumps are often used when the drain field is located higher than your holding tank, and many states require them by law.

Solid Handling Pumps:

These pumps are made to pump raw sewage. Most pumps, however, can’t handle a large amount of solid matter found in raw sewage; only special Solid handling pumps should be used where there’s a need to move this type of waste around.

Construction:

Impeller:

The impeller is connected to the motor shaft in the volute. It is a rotor to increase pressure and fluid flow. It encompasses the eye (where the fluid enters), The veins (pushes the fluid), and the channel where the fluid flows. Lastly, it also has where the motor shafts are attached, called the bore.

There are two types of impellers: single-suction and double. Single-suction impellers draw fluid in through one direction, while double suction varieties draw it in from both sides simultaneously.

The impeller has three common configurations: open, semi-open, and closed. Open impellers have vanes attached to a central unit and allow solid particles to pass through. Semi-open impellers contain the vanes in a wear ring design so that solid particles can pass through while liquids remain contained within and Closed impellers have a wear ring that completely surrounds the vanes, protecting these components from degradation over time.

Diffuser:

The diffuser is designed to alter the flow rate and increase pressure, thereby increasing efficiency. The diffuser can be part of either an impeller or the inside wall of a pipe where fluid flows; vanes are also often used.

Some pumps, such as submersible well pumps, will be multi-stage. These have multiple levels: the first contains the impeller; each subsequent level is a diffuser that slows down water speed in stages before it reaches another impeller that whips it up to full velocity again, only for this process to repeat all over again!

Note: It is important to understand how each component works together for the pump to function properly. A motor powers a shaft that spins an impeller, creating suction that brings water into the volute through an inlet pipe and ejects it out through a discharge outlet.

Motor:

The pump’s next main component is the motor or drive. The motor converts electrical energy into mechanical energy to push fluid through pipes and down pressure drops. Fan-cooled (TEFC) motors are common in many applications, while oil-cooled (ODP) models provide better performance at higher temperatures.

Parts of the motor

Rotor: This is the part that moves the shaft by rotating.

Stator: It is the stationary part of the motor’s electromagnetic circuit.

Windings: Wires that are laid in coils to form magnetic poles when energized with the current. They are usually wrapped around a laminated soft iron magnetic core.

Commutator: It consists of slip ring segments for switching the input of DC machines and certain AC machines.

Spline shaft: This shaft delivers the mechanical power from the motor to the volute.

Shaft sleeve or bearing: Supports the applied load while allowing the motion of the shaft and reducing friction.

Mechanical Seal: It minimizes fluid leakage between the rotating shaft and stationary casing by maintaining contact at a sealing interface. Two faces, one rotates with the shaft as it turns while another remains in place.

For the motor to start operating, there must be a power source where the electricity will be supplied to the motor. Ensure that the power cable used for this purpose is strong and has a lot of strands to manage the power going to the motor without melting.

How to install a septic tank pump:

Here is step by step procedure of installing septic tank pump.

Circuit Breaker Installation

Step 1

Turn the main breakers off, and then disconnect the power at the meter. Use a flashlight to see what you do while installing circuit breakers.

Step 2

Install a 20-AMP GFI and 15-AMP standard circuit breakers inside the existing breaker box. Look for a black wire held in place by screws. Loosen the screw, attach one end of the black circuit wire, and then tighten it back into place.

For GFI breakers, there is white neutral nylon interwoven with black wires. Connect this as well before tightening your screws down again.

Step 3

Plug them into place by holding breakers at an angle and pushing until they snap onto the metal bar inside the breaker box. The two notches in each circuit breaker are designed to slide over the metal bus bars on the back of the panel.

Outlet Installation and Ground Wiring

Step 1

Mount a junction box and 20-amp outlet near the septic tank. The outlet is for the pump, and you’ll also need to wire up an alarm float. Make sure that the box is properly grounded before burying it at least 16 inches deep, and then pour some concrete around it afterward just to be safe.

Step 2

Dig out a 2-foot trench from the septic tank back to your breaker box if you want to underground wire. Use shovels or heavy machinery depending upon how far apart things are. You can contact a professional to dig the trenches for you.

Step 3

Connect a 12-gauge wire to a 20 amp outlet, run a 14-gauge wire from the junction box mounted on the post, and connect it to breakers in your breaker box. Then run all of these wires through the conduit and secure them tightly enough. The 12-gauge wire from the outlet for the sump pump connects to the 20-AMP GFI breaker, while 14-gauge wires used for alarm float wiring are connected to standard breakers.

Pump and Alarm Setup

Step 1

Use tie straps or the included materials to secure the float switch for a high-water alarm at the desired water level in your septic tank. Wire the float switch to a junction box on the post and then connect it to a 14-gauge wire, which will run back to your breaker box. Install all remaining high water alarm components as specified by manufacturers.

Step 2

Use a pipe cleaner to clean the discharge pipe and allow it to dry completely before connecting it to the outlet of your submersible septic pump. Secure them using pipe dope, then connect fittings. The pipe should be as long as the height of the septic tank, and one end will connect to a drainage pipe leading away from the distribution tank once water is pumped into it.

Step 3

Tie the rope or cable to a nearby post, and lower the pump into your septic tank. Connect one end of that section of drainage pipe with your current system heading to the house and let everything dry before reconnecting power to operate properly.

Conclusion:

Septic tank pumps are very vital, especially if you are far from the main sewer lines, and therefore it also calls for proper maintenance to ensure that it works properly. It usually lasts very long when you install it with a circuit breaker to protect it from any power surge that could spoil the motor.

Regular septic tank pump maintenance is integral to the health of your entire septic system. To prevent maintenance costs and extend the life of your system, do not clean or drain, Dental floss, Personal care products, Baby wipes, and Cotton swabs, among others. You can also avoid utilizing waste disposal methods since they fill septic tanks quickly and get water inside the tanks. With these, you will enjoy your septic tank services for a very long time.