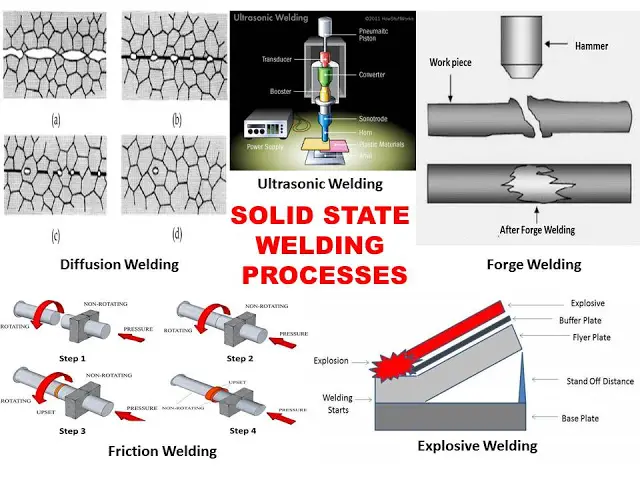

Today we will learn about solid state welding process principle, types, application, advantages and disadvantages. Solid state welding processes are those welding processes in which no external heat is applied and the joining of work piece takes place in solid state. In these welding processes, no filler metal is used and welding does not involve molten state of base material or filler material. The weld formation take place due to inter molecular diffusion process in which, the interface molecules of work pieces flows from high concentration region to low concentration region due to applied pressure. Some methods are used to produce heat which accelerates diffusion process at mating surfaces. This type of welding processes does not affect the mechanical or physical properties of parent material thus these are widely used in industries application. These are ideal joining processes for heat sensitive material.

Solid State Welding Process:

Principle:

Mainly metal joining process is classified into two types. The first one is liquid state welding process in which, metal work pieces are heated until its melting temperature and the metal to metal joint form due to solidification of melted work pieces together. Sometimes this process uses filler material which is melted with base material and allow to solidity, which make a permanent strong joint. The other one is solid state welding process in which no molten or liquid state involves and metal joining process takes place due to application of high pressure into solid state. The metal to metal joint form due to inter molecular diffusion process at the interface surfaces. This is basic principle of it.

Types:

We have discussed about main principle of solid state welding processes. All solid state welding processes work on same principle but the method of applying pressure and heat is different in all these processes. According to application of energy this welding process can be classified into following types.

Forge Welding:

Forge welding works on basic principle of forging. In this type of welding process, both welding plates heated simultaneously quite below its melting temperature. This heating deforms the work pieces plastically. Now a repeated hammering on these plates applied together. This hammering starts diffusion process between plates and repeated continuously until whole joint is created. It was used to weld iron or steal work pieces into ancient time.

Friction Welding:

As the name implies, this welding uses friction heat to accelerate diffusion process. In this type of welding, a rotating work piece bring in contact with a stable work piece. Due to high friction force at the contact surfaces, a high amount of heat generates. The friction is applied until the plastic form at interface surface is achieved. After this heating process, a continuously increase pressure force applied on these work pieces until whole joint is form. This welding mostly used to join steel bars, tubes etc. One of the most important type of friction welding is friction stir welding in which, a non-consumable rotating tool is used to applied friction of welding plates.

Ultrasonic Welding:

Ultrasonic welding is also a solid state welding process in which energy of ultrasonic waves is used to join two work pieces. In this process, ultrasonic vibration create dynamic shear between the interface surfaces. This will create local plastic deformation and friction between plates which is used to create joint at interface part.

Explosive Welding:

This welding uses explosive energy to joint two plates. In this process both the welding plates placed one over another such that the welding surface is in contact with one another. Now a buffer plate is placed over upper surface of welding plate which protects welding plates form high impact force of explosive. The explosive is placed over buffer plate. When the explosion starts, a high pressure wave generates which deform the interface surface of welding plates plastically and form a metallurgical bond between these plates. This joint is stronger than parent material. It is mostly used to weld large welding area.

Diffusion Bonding:

Diffusion mean flow of any material form high concentration region to low concentration region. This is basic principle of diffusion bonding. In this welding method, both the welding plates are placed one over another in presence of high pressure and temperature for long time. This high pressure starts diffusion between interface surfaces of welding plates. This diffusion accelerates by the high temperature which is much below melting temperature of base plates. No molten state involves in this type of welding and weld joint is form in pure solid state.

Application:

Solid state weldings are used in every where in mechanical industries. It is widely used in aerospace and marine industries for structure work. It is widely used in automobile industries for most of fabrication work. Explosive welding used to join large welding plate which can’t be possible or uneconomical by other methods like arc welding or gas welding. Friction welding is used to join tubes, shaft etc. These process are further used to join dissimilar material used in various industries. Hydraulic piston, connecting rod, drive line, truck roller bushes, pump shaft, gear lever, drill bit etc. are friction welded.

Advantages and Disadvantages:

Advantages:

- Solid state welding can be easily automated.

- This produces high strength joint without applying external heat.

- They are used to weld both similar and dissimilar material.

- Provide good surface finish.

- They does not use any filler metal or flux as used in arc welding.

- Mostly these processes do not affect properties of parent materials.

Disadvantages:

- High equipment cost or set up cost.

- Welding preparation is more critical.

- Complicated and special fixtures are required for different process.

- Mostly, these process can’t be used for mass production due to slow welding speed.

This is all about solid state welding process principle, working, types, application, advantages and disadvantages. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on your social networks. Subscribe our website for more interesting articles. Thanks of reading it.

How the criteria for welding are met in case of a solid state welding process