Compressor is a mechanical device which is used to increase the pressure of air/gas. Air is generally compressible that’s why compressor increase the pressure of air by reducing its volume. It has several applications like in refrigeration and air conditioning, in industrial automation where pneumatic actuators are used. In different applications different types of air compressor are required. All the compressors have same basic principle but have different applications and working criterion. The important types of air compressor are categorized in the following manner.

Types of Air Compressor:

Dynamic type

- Centrifugal compressors

- Axial compressors

Positive displacement

- Rotary compressors

- Lobe compressors

- Rotary screw compressors

- Scroll compressors

- Rotary vane compressors

2. Reciprocating compressors

- Single acting

- Double acting

- Diaphragm

Dynamic Compressors:

When we talk about dynamic then it relates with the forces which produce some kind of motion. Same case is here dynamic compressors deal with the momentum of the air. In these types of compressors rotating impeller generated dynamic moment which increase the pressure of flowing air. Dynamic compressors have large applications in the petroleum and chemical industries where continuous work is required in long run. The dynamic compressors further divided into two sub-categories centrifugal and axial compressors.

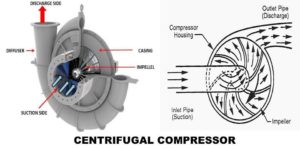

1. Centrifugal compressors:

It is continuous flow compressor. Centrifugal compressors are the mixed flow compressors in which air enters into the compressors axially and comes out radially. The dynamic action is provided to air by means of rotating impellers. Rotating impellers provide high inertial forces to the air. Air flow through the compressor goes through the several stages, in each stage air goes through impeller (moving element) and diffuser (stationery element) where it loses its velocity and gain pressure. At the end of all the stages highly compressed air comes out. Centrifugal compressor used at small scale where less pressure of air is required because it has small flow rate and low efficiency. The main advantage of this compressor is its cost because it is easy to manufacture.

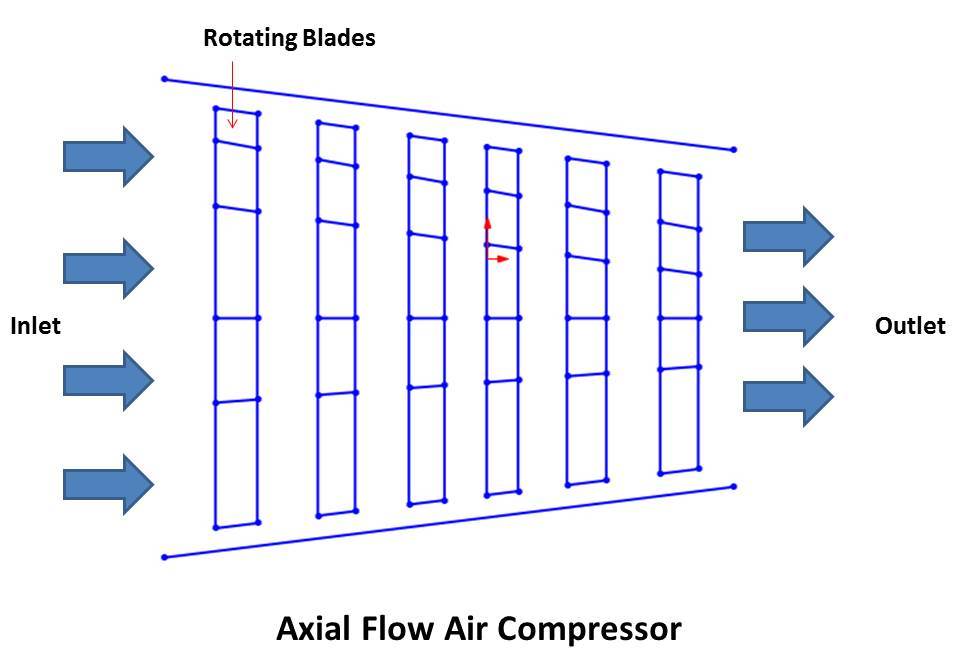

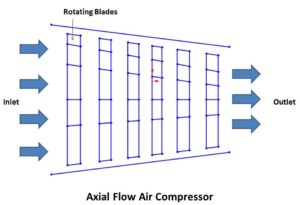

2. Axial flow compressors:

Axial flow is another type of dynamic flow air compressor i.e. air is compressed by the dynamic action of the rotary elements. As name implies flow takes place parallel to the axis of rotation in the compressor. The rotor of the axial flow air compressor has several rows of airflows which help it to compress the air at high pressure. It continuously compresses the air. The rotor of the compressor consists of several stationery and rotating blades. Rotating blade provides torque to the air and stationery blades reduce the velocity of flowing air. As air enters into the compressor it has high velocity and low pressure but at the end air is fully compressed. Due to the several blade arrangements the structure of compressor is bulky and complex which increases its cost. The main advantage of axial flow compressor is its high efficiency and it provides high mass flow rate.

Positive Displacement compressors:

As name suggests positive displacement compressor work by means of displacing fluid by using some mechanism or we can say that any small mechanical linkage like gears, piston and rotors etc. It compresses small-small amount of air which enters through one side and comes out from the second side with high pressure, in between air goes through the several mechanical linkages. According to the type of mechanical linkage positive displacement compressors are sub-divided into rotary and reciprocating compressors.

1. Rotary compressors:

In rotary compressor a rotating linkage rotates inside the cylinder. According to the type of rotating linkage, rotary compressors are divided into further categories but if we talk about simple rotary compressors, it has a fixed shaft which is offset to the centre into a cylinder and a roller rotates around the shaft by means of external force. Some part of the rotor always contacts with cylinder internally. From one side it sucks air and delivers it to other side after rotating of roller. It deals in small mass flow rate where continuous work is required. Further types of rotary compressors are explained below:

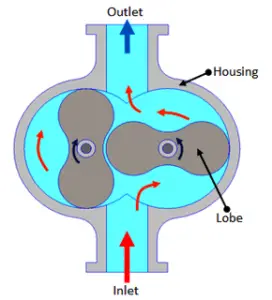

a) Lobe compressors:

It is a small kind of compressor which deals with very low pressure i.e. 1 bar to 2 bar. It is a type of blower which works in 2 stages. Two lobe shape rotors rotate in parallel to each other in mechanical linkage like gears. It sucks small pocket of air and deliver to second end after compression. It is used in low pressure applications.

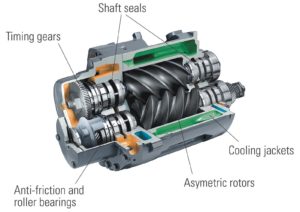

b) Rotary screw compressors:

As name implies rotary compressors consists of two rotating screws linked parallel to each other. Generally helical screws are preferred for positive displacement between the screws. When both the screws revolve on each other then only a small passage is remaining for the flow of air, when air goes through this small passage from one side to second side it loses its velocity and gain pressure. It is very simple in construction and easy to use. Very less wear and tear take place in it that’s why it is preferred in the most of the industries. It is a small compressor which makes it portable and suitable for commercial applications.

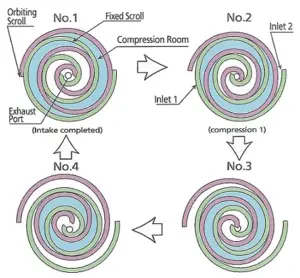

c) Scroll compressor:

It is one of the best compressors in low mass flow rate category. It consists of two spiral vanes which are connected like a scoop form. One spiral vane is always fixed while the second one is linked to first spiral with some eccentricity. Second spiral revolve on fixed spiral in eccentric manner. The gap between two spiral vanes varies circumstantially and at the end very small gap is left. When air goes between these two spiral vanes it gains pressure. It works very smoothly which makes it more efficient than any other compressor of its kind.

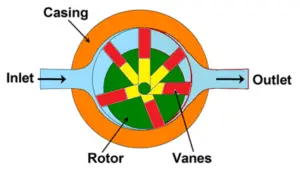

d) Rotary vane compressor:

As per the name this compressor consists of several rotating vanes/blades which are attached on a rotor. It is one of the oldest compressor which is still in use in various applications because of its highest mechanical efficiency which is about 80-90%. The rotor of the compressor is mounted inside a housing. The housing has complex geometry which provides very narrow passage for the flow of air. When rotor is rotating then vanes change the position which decrease the volume of air and increase the pressure.

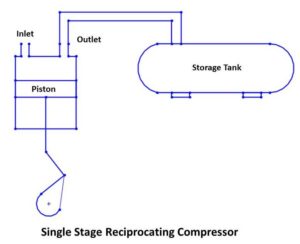

2. Reciprocating compressor:

It is another type of positive displacement compressor. A piston is responsible for the reciprocating action inside the cylinder. It has very simple construction and working. It has a cylinder having two ports; one is for inlet air and second is for delivery. When air enters through first port second port remains close. After suction inlet port also close then piston moves up and compresses the air and decreases its volume after that delivery port open and compressed air goes out. This cycle is repeated continuously. At the end it delivers air at very high pressure. Following are the three main types of reciprocating compressor.

a) Single Acting:

It is a simple type of reciprocating compressor. It works at the single side movement of the piston and the working is same as explained above in reciprocating compressor.

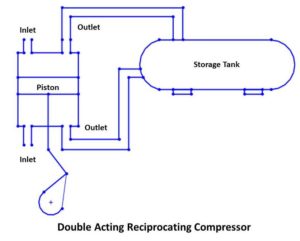

b) Double Acting:

In double acting, piston is active on both the sides which provides high mass flow rate as compare to single acting compressor at very high pressure. In double acting continuous delivery is obtained by the reciprocating action of the piston. At the same time both suction and compression stroke take place, which makes it highly efficient. It has various industrial applications where very high pressure is required.

c) Diaphragm compressor:

It is another type of reciprocating compressor which is also known as membrane compressor because it consists of several membranes. These membranes reciprocate by means of crankshaft and piston. As the piston rod moves it creates a vacuum which sucks the air inside the chamber and then compress it after that compressed air goes to the outlet. It has very fewer applications where low pressure is required.

This is all about different types of air compressor. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more informative articles. Thanks for reading it.

Pingback: How a Helicopter Fly and Constructed? - mech4study