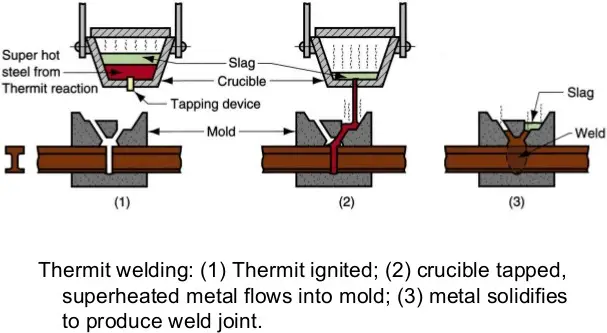

Thermite Welding: Principle, Working, Equipment’s, Application, Advantages and Disadvantages

Today we will learn about thermite welding, principle, working, equipment’s, application, advantages and disadvantages. Thermite welding is a liquid state welding process in which the metal to metal joint created by melting of base material or applying filler material in liquid form. This welding is further classified into chemical welding process because the heat required …