Today we will learn about types of pattern used in casting. Pattern is replica or model of object which to be created. It is used to make hollow cavity in sand mold in which molten metal is poured and allow solidifying to create object. The size and shape of cast object is highly depends of shape and size of pattern. Mostly pattern are made by aluminum, wood, wax etc. Metal pattern are used for mass production. The pattern making is most critical work in casting because the object is highly depended on it. A good pattern should follow following requirements.

- Low cost and easy to cast.

- Easy to repair.

- It should light in weight which make it easy to handle.

- It should able to withstand ramming forces without deformation.

- It should does not change its dimensions in presence of moisture.

- It should be easily removable from mould.

- It should have long life without change in its dimensions.

Also Read : Types of Casting

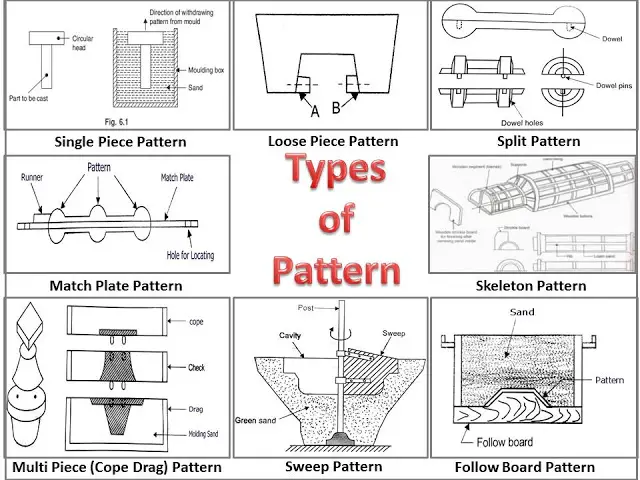

Types of pattern:

As we discussed, casting objects are highly depend on pattern. According to the shape and size of casting and method of making cavity, pattern can be classified as follow.

Single Piece Pattern:

It is simplest type of pattern which is made in single piece. It is used for simple objects. It is either placed into cope or in drag according to the simplicity of operation. It is used to cast stuffing box of steam engines.

Split Pattern or Multi Piece Pattern:

These patterns are made into two or more pieces. The first half of pattern placed into cope and other half into drag. It is used for complex objects where removal of single piece pattern from mould is impossible. When pattern is made in more than three parts cheeks are also used for easy removal.

Cope and Drag Pattern:

These are two piece split pattern as discussed above. It is used for large objects

Match Plate Pattern:

Match plate pattern is a split pattern in which cope and drag section mounted on opposite sides of a plate. The plate is known as match plate. These will make easy to cast any shape with high production rate. Mostly runner, gates etc. are also mounted on same plate which will easy to mould making work. These patterns are used for mass production.

Loose Piece Pattern:

When removal of pattern is impossible due to an extended surface at either upper half or lower half, the extended part made as loose piece so this extended part can be removed first before removal of whole pattern. This will make easy removal of pattern without effect on the cavity. These patterns are known as loose piece pattern.

Gated Pattern:

These are simply more than one looses piece which are attached with a common gating system. These are used for mass production. It is used to produce small size cavities into one mould.

Sweep Pattern:

These pattern are used for large rotational symmetrical casting. A sweep is a section of large symmetrical object which is rotated along a edge into sand which make a large symmetrical mould. These patterns makes easy pattern making work of large objects.

Skeleton Pattern:

These patterns used for large simple castings. In these patterns, skeleton like structure made by using simple pattern sections. These will save both time and material.

Follow Board Pattern:

Follow board is a wooden board which is used to support pattern during moulding. It acts as sit for pattern.

These are all about what is Pattern and types of pattern used in casting. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more interesting articles. Thanks for reading it.

Simple language is used which is helpful for me

Yes

simple to learn

nice blog

patse the pictures with the specific patterns so we csn easily understand different types of patterns used in casting process.

Nice to study and understand

It’s really useful