Today we will learn about different types of allowance used in pattern making. The pattern is replica of casting but it has slightly large dimension. This change in dimensions in pattern and casting are due to various allowance used in casting. When the cast solidify, it shrink at some extent due to metal shrinkage property during cooling, so a pattern make slightly larger to compensate it. There are another reasons which are due to poor surface finish and casting limitations, casting make slightly larger so it can machine or polish further. So the pattern hence cavity for casting forms slightly larger which can compensate all these drawbacks of casting. The change in dimensions of pattern and casting are known as allowance.

Types of Pattern Allowance:

Allowance can be classified into following types.

Shrinkage allowance:

Shrinkage is defined as reduce the dimension of casting during solidification or during cooling. This is general property of all materials. Some metal shrinks more, some less but every material shrinks. There are three types of shrinkage.

1. Liquid Shrinkage

2. Solidification Shrinkage

3. Solid Shrinkage

The liquid shrinkage and solidification shrinkage are compensated by suitable riser but solid shrinkage does not compensated by it so the pattern is made slightly larger to compensate shrinkage. This is known as shrinkage allowance.

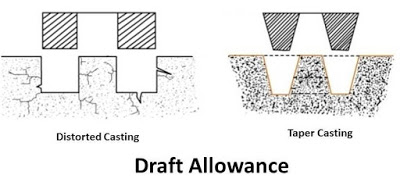

Draft Allowance:

When the pattern is removed from mould, the parallel surface to the direction at which pattern is withdrawn, damaged slightly and convert into slightly tapered surfaces. To compensate these changes, these parallel surfaces on patterns are made slightly tapered (1-2 degree). This allow easy removal of pattern from mold and does not affect the actual dimension of casting. These are known as draft allowance.

Machining Allowance:

As we known the casting gives poor surface finish and rough surfaces. Also, the Pattern is made manually which does not fixed accurate angles and dimensions of mating parts. But we need a proper finished and dimensionaly accurate casting. To avoid these problems, casting made slightly larger and after solidification machining is done on it for better surface finish and accurate dimensions. This change in dimension of casting is known as machining allowance.

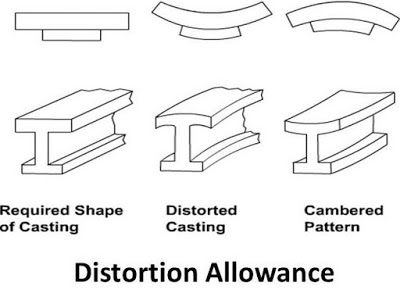

Distortion Allowance:

When casting of very thin surfaces like V Shape, U shape etc. it will distort or damage during pattern removal or during casting. To avoid this problem, a chamber is provided on pattern to compensate distortion during pattern removal. This change in casting dimension is known as distortion allowance.

Rapping Allowance:

When the pattern is removed from casting, it will slightly increase the dimension of casting. So to compensate this changes, the pattern is made slightly smaller from casting. This change in dimension is known as rapping allowance.

These are all main types of allowance which are considered in pattern making. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more interesting articles. Thanks for reading it.

Nice