Today we will learn about what is forging and types of forging. Further we will discuss about operation, application, advantages and disadvantages of this process. Forging is a metal forming process in which the metal is heated and a force is applied in such a way that a required shape can be obtain. It is basically a hot working process in which the work piece is heated up to plastic stage and the force is applied by manually or by press according to the requirement. This force is compressive in nature which is basic requirement of forging. Sometime forging operation is done without application of heat known as cold forging. Now days, Forging is used in every manufacturing industries.

What is Forging Process?

Operation:

Mainly forging consist two operations according to the force applied.

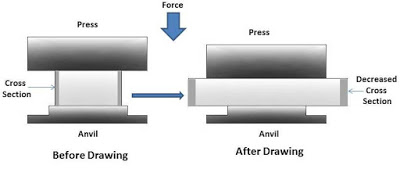

1.) Drawing Down:

Drawing down is a process of elongate the length and reduce the cross section area of work piece. Simply in this operation, the length of work piece increases and the cross section area decreases. In this process, a compressive force is applied at perpendicular direction of its length axis. If a tensile force is applied to change its length at parallel to its length axis, this process is known as wire drawing.

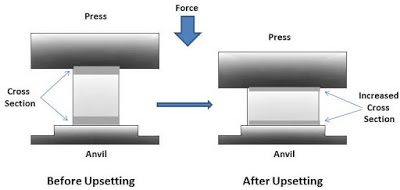

2.) Upsetting:

Upsetting is just opposite operation to drawing down. In this operation, the length of work piece decreases and its cross section area increases. In this process, a compressive force is applied at parallel direction to its length axis.

Types of Forging:

Forging may be classified into following ways.

1.) According to the Temperature:

a.) Hot Forging:

If the work piece is heated above its recrystallization temperature and then force is applied, the process is known as hot forging. The recrystallization temperature of most of metals is half of its melting temperature.

b.) Warm Forging:

Warm forging done at the temperature about 40 percent of its melting point temperature.

c.) Cold Forging:

Cold forging is done at room temperature. This process gives highest mechanical properties among all forging processes.

2.) According to arrangement of Die:

a.) Open Die Forging:

This forging process uses flat dies or no die. This is mostly hot forging process in which the work piece heated and hammered to obtain desire shape. This process produce rough product.

b.) Close Die Forging:

Close die forging is a process in which a set of impression die is used to produce desire shape on work piece. Mostly these products do not need any finishing process. This process required higher force.

3.) According to the Forging equipment:

a.) Smith forging:

Smith forging is traditional method of metal forming. It is open die forging method in which the work piece is placed on a stationary anvil and a hammer strikes and deform the work piece. The force is applied either by manually or power hammers.

b.) Drop Forging:

Drop forging is done in closed impression dies. An automatic

hammer applied the force in series of blow by dropping action. In this type, a sudden applied force is used.

hammer applied the force in series of blow by dropping action. In this type, a sudden applied force is used.

c.) Press Forging:

Press forging is similar to drop forging except it uses continuous squeezing type applied force by the hydraulic press. This process increase the length and decrease its cross section of work piece.

d.) Machine Forging:

Machining forging is an upsetting process in which the cross section of work piece increases and length decreases.

Advantages and Disadvantages:

Advantages:

- Forging gives comparatively tougher product compare to casting.

- The fatigue strength and creep resistance of forge product is higher.

- Forge product has higher mechanical properties.

- Low cost operation.

- This process does not required special skill operator.

- Variety of shapes can be formed by this process.

Disadvantages:

- Higher initial cost for big forging presses.

- Secondary finishing process required in hot forging.

- It cannot produce complex shapes.

- Size is limited due to size of press.

- Brittle metal cannot be forged.

Application of Forging:

- Mainly forged products are used in every mechanical industry.

- Turbine rotor, generator rotor etc. are forged product.

- It gives higher fatigue strength so most of moving parts like crankshaft, camshaft gears etc. are made by forging operation.

- Cold forging is used to produce chisel, bolts etc.

- These are mostly used in hand tools and hardware manufacturing.

- It is used in ship building in various structure works.

This is all about what is forging process, operation, types, application, advantages and disadvantages. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it with your friends. Subscribe our website for more interesting articles. Thanks for reading it.

it was helpful, thanks

Nice explanation about Forging.

Do you guys have any articles regarding scrap reduction during forging ooerations and to how to reduce it?

Elaborate almost all information about forging in very easy language and systematically. It is very helpful for me.I am preparing for AMIE examination.A . My self confidence has increased after reading this lecture. Many Many thanks for this.

Forging is the process of heating a metal to a very disred temperature in order to aquire sufficient plasticity .