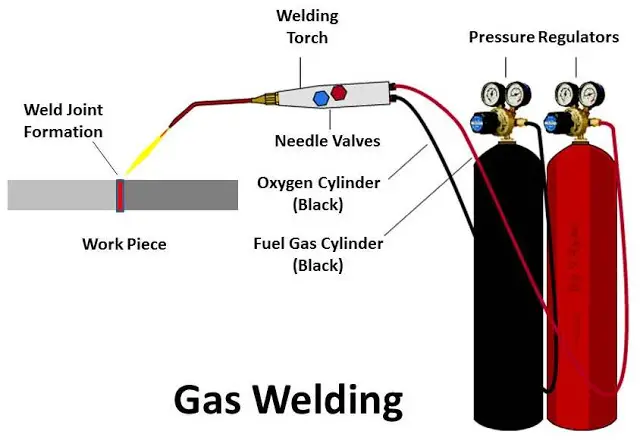

Today we will learn about gas welding and its principle, working, equipment’s, types, application, advantages and disadvantages. Gas welding is a type of liquid state welding process in which fuel gases burns to generate heat. This heat is further used to melt interface surfaces of welding plates which are held together to form a joint. In this process, mostly oxy-acetylene gas is used as fuel gas. This process can be done with or without help of filler material. If the filler material is used, it is fed directly into the weld area manually.

Gas welding is mostly used in every industrial processes which require welded joints. The term welding is define to join two similar or dissimilar metals with the application of heat. The heat provided in this welding is by burning of fuel gases like hydrogen, LPG, Oxy acetylene etc.

Gas Welding:

What is Gas Welding?

Gas welding is a most important type of welding process. It is done by burning of fuel gases with the help of oxygen which forms a concentrated flame of high temperature. This flame directly strikes the weld area and melts the weld surface and filler material. The melted part of welding plates diffused in one another and create a weld joint after cooling. This welding method can be used to join most of common metals used in daily life.

Equipment used for gas welding:

Welding Torch:

Welding torches are most important part of gas welding. Both the fuel gas and oxygen at suitable pressure fed through hoses to the welding torch. There are valves for each gas witch control the flow of gases inside the torch. Both gases mixed there and form a flammable mixture. These gases ignite to burn at the nozzle. The fire flame flow through nozzle and strikes at welding plates. The nozzle thickness depends on the size of the welding plates and material to be welded.

Oxygen Cylinder:

For proper burning of fuel, appropriate amount of oxygen required. This oxygen supplied by a oxygen cylinder. A black line is used to indicate oxygen cylinder.

Fuel Gas Cylinder:

Gas cylinder is filled either by oxy acetylene gas, hydrogen gas, natural gas or other flammable gas. The fuel gas selection is depends on the welding material. Mostly oxy acetylene gas is used for all general purpose of welding. Normally these cylinders have Maroon line to indicate it. The fuel gases passes through it.

Pressure regulator:

Both oxygen and fuel gases are filled in cylinder at high pressure. These gases cannot use at this high pressure for welding work so a pressure regulator is used between flow. It supplies oxygen at pressure about 70 – 130 KN / M2 and gas at 7 – 103 KN / M2 to the welding torch.

Goggles and Gloves:

These are use for safety purpose of welder. It protects eyes and hand from radiation and flame of fire.

How Gas Welding Works?

Gas welding process is quite simpler compare to arc welding. In this process all the equipment are connected carefully. The gas cylinder and oxygen cylinder

connected to the welding torch through pressure regulators. Now the regulate pressure of gas and oxygen supplied to the torch where they properly mixed. The flame is ignited by a striker. Take care the tip of torch is pointing downward. Now the flame is controlled through valves situated in welding torch. The flame is set at natural flame or carburizing flame or oxidizing flame according to the welding condition. Now the welding torch moved along the line where joint to be created. This will melt the interface part and join them permanently.

connected to the welding torch through pressure regulators. Now the regulate pressure of gas and oxygen supplied to the torch where they properly mixed. The flame is ignited by a striker. Take care the tip of torch is pointing downward. Now the flame is controlled through valves situated in welding torch. The flame is set at natural flame or carburizing flame or oxidizing flame according to the welding condition. Now the welding torch moved along the line where joint to be created. This will melt the interface part and join them permanently.

Application:

- It is used to join thin metal plates.

- It can used to join both ferrous and non-ferrous metals.

- Gas welding mostly used in fabrication of sheet metal.

- It is widely used in automobile and aircraft industries.

Advantages and Disadvantages:

Advantages:

- It is easy to operate and dose not required high skill operator.

- Equipment cost is low compare to other welding processes like MIG, TIG etc.

- It can be used at site.

- Equipment’s are more portable than other type of welding.

- It can also be used as gas cutting.

Disadvantages:

- It provides low surface finish. This process needs a finishing operation after welding.

- Gas welding have large heat affected zone which can cause change in mechanical properties of parent material.

- Higher safety issue due to naked flame of high temperature.

- It is Suitable only for soft and thin sheets.

- Slow metal joining rate.

- No shielding area which causes more welding defects.

This is all about gas welding principle, equipment’s, working, application, advantages and disadvantages. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more interesting articles. Thanks for reading it.

Image Source : http://www.technologystudent.com/equip_flsh/acet1.html

I do accept as true with all the concepts you have offered to your post. They are very convincing and will definitely work. Still, the posts are very brief for newbies. May you please extend them a bit from subsequent time? Thanks for the post.

Why is the gas fuel cylinder room surrounded with number of holes either on walls or at doors?

Due to leakage of gas is very hazardous…..

How to operate torch regulator

Thanks for this informative and detailed article.

Nice explanation sir……..

And it is to understanding method…..

Nice Post and give all basic details which are required

Thanks

Good one but i may know weder the simple precautions that involved in gas welding

fuel gas is maroon not black in colour

NICE POST.IS MY JOB 30YEARS OF AGE. 17YEARS EXPERIENCE.

WHAT ABOUT PRESSURE ? IS ALLTYPES OF THICKNESSED METALS USED SAME PRESSURE ?

Pingback: Underwater Welder Salary -How Much They Earn? - mech4study

gos welding job

GOOD DESCRIPTION , VERY MUCH INFORMATIVE. THE PICTURE SHOWS BOTH OXYGEN & FUEL CYCLINDER MARKINGS AS BLACK, KINDLY CHECK FOR CORRECTION.