What will you learn from this article?

- Main Part of Four Stroke SI and CI Engines.

- Concept of Working of Four Stroke Spark Ignition (Petrol) and Compression Ignition (Diesel) engines with its applications.

- Advantage and Disadvantages of Four Stroke engines.

In our previous articles, we have learnt about engine types and its main parts along with terminology used in engine. We know an IC engine can be classified through many ways. One of the most useful engine is a four stroke engine which is mostly used in automobile industries. These engines can be further classified into spark ignition engine or petrol engine and compression ignition engine or diesel engine. The SI engine is developed by Nicolaus Otto and CI engine is developed by Rudolf Diesel. These engines have many similarities with some fundamental differences.

Four Stroke Engine:

Principle:

We know that stroke is define as maximum movement of piston in any direction inside engine cylinder. For example if a piston moves form bottom dead center to top dead center is known as a stroke. If it returns back to bottom dead center, it is known as 2 stroke. Similarly, if it again moves towards TDC and come back BDC, it completes four strokes. This is basic principle of four stroke engine.

An engine which completes four strokes into one power stroke or to complete one cycle is called four stroke engine. The crankshaft completes one revolution in two strokes. So it rotates two revolution in four strokes engines.

Parts:

1. Piston

2. Cylinder

3. Combustion Chamber

4. Inlet and Exhaust Valves

5. Inlet and Exhaust Manifold

6. Spark Plug

7. Injector

8. Connecting Rod

9. Crankshaft

10. Piston Rings

11. Gudgeon Pin

12. Camshaft

13. Flywheel

14. Crankcase

You can learn more about these Parts by Basic Parts of Engines

Working of Four Stroke Engine:

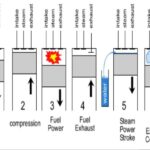

A four stroke engine completes it’s cyclic operation into four strokes of piston or two revolution of crankshaft. These strokes are suction stroke, compression stroke, power or expansion stroke and exhaust stroke. Both SI and CI engines follow these four strokes to complete one cycle. The working operation of these strokes can be summarize as follow.

Suction Stroke:

Suction means drawing charge (air fuel mixture in SI engines and air alone in CI engines) into engine cylinder. It is drawn through inlet valve. Piston moves from TDC to BDC during this stroke. The air is sucked due to pressure difference between engine cylinder and atmosphere in non-supercharged engine and by an air compressor in supercharged engines.

Compression Stroke:

In this stroke, piston moves from BDC to TDC. Both inlet and exhaust valves closed and the piston compressed charge during this stroke. The movement of piston is due to inertia or cranking of engine. This process takes place isentropic ally in both SI ad CI engines.

Power and Expansion Stroke:

In this stroke, piston moves from TDC to BDC. Both inlet and exhaust valve closed during this stroke.

In SI engines, spark plug generates a spark which ignites the fuel air mixture. Because total fuel is available inside the cylinder, the burning takes place instantly so this process considered as constant volume burning for ideal cycle. Due to burning of fuel a high pressure force generates inside the cylinder which act as driving force of piston and crankshaft. After burning, piston expands from TDC to BDC at isentropic ally.

In CI engines, injector injects fuel into combustion chamber. The fuel burns due to heat generated during compression stroke. In these engines, fuel is supplied through injector so burring of fuel does not takes place instantly. The fuel burn uniformly, so this process considered as constant pressure burning for ideal cycle. After burning, the piston moves from TDC to BDC at isentropic ally.

Exhaust Stroke:

When piston reaches BDC, the exhaust valve opens and piston start moving from BDC to TDC due to inertia of piston. The burnt gases exhausted from exhaust valve from engine cylinder to environment. When the piston reaches TDC, new charge enters into cylinder and this cycle repeats itself.

Application of Four Stroke Engine:

- Four stroke engine widely used in automobile industries.

- They are used in bus, trucks and other transportation vehicles.

- They are used in pumping system.

- These engines find application in mobile electric generators.

- These engines widely used in aircraft and marine engines.

- Diesel engines find application in pump sets, construction machinery, air compressor, drilling rigs, etc.

Advantages and Disadvantages:

Advantages:

- Four stroke engines give higher efficiency.

- It creates less pollution.

- Less wear and tear due to good lubrication system

- It is quitter in operation.

- It runs cleaner due to no extra oil added in fuel.

- They give high rpm at low power.

Disadvantages:

- These engines are more complicated due to valve mechanism and lubrication system.

- These are costly compare to two stroke engines.

- Four stroke engines gives less power.

Now you should ask yourself these questions.

What are main components of four stroke engine?

What is stroke? How engine four stroke engine produces power?

What are advantages of four stroke engines?

If you like this article, asks questions in comment box, share it on your social network and subscribe our website.

Pingback: Two Stroke Engine: Main Parts, Principle, Working, Application, Advantages and Disadvantages - mech4study

The way explained super sir , but you also add some content like volumetric efficiency.compreasion ratio, mechanical efficiency .. its my suggestion sir tq

Nice post about technologies thanks sir I really inspired.