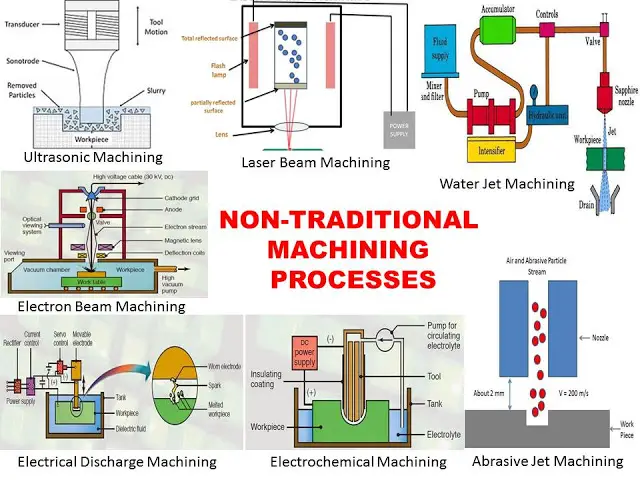

Non-Traditional Machining Process: Requirements, Types, Advantages and Disadvantages

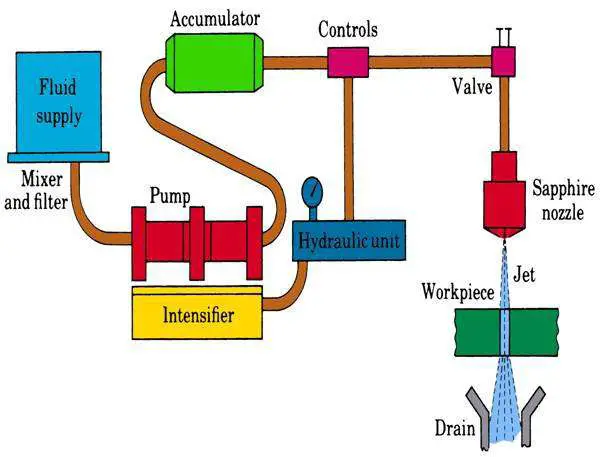

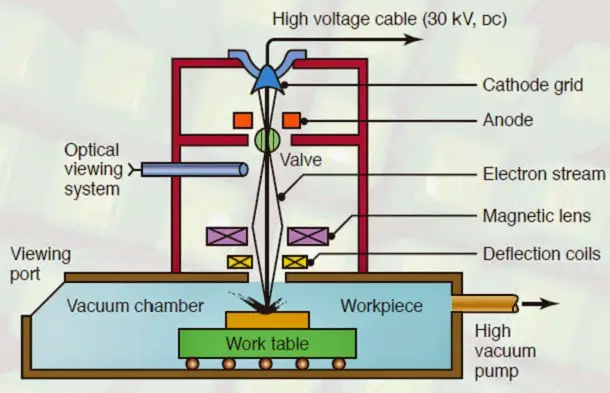

Today we will learn about Non-traditional machining processes requirement, types, advantages and disadvantages. Machining is one of the most important process of metal forming and shaping. Mostly, it is used in all manufacturing processes. In the convention machining processes, tool is in direct contact with work piece. There are many disadvantages and limitations of conventional …

Non-Traditional Machining Process: Requirements, Types, Advantages and Disadvantages Read More »