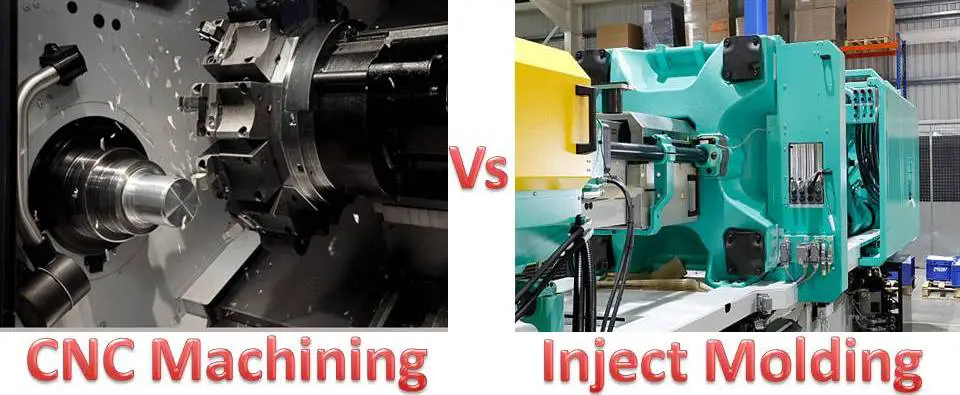

When designing and manufacturing parts for your products, several manufacturing methods are to consider. The two most common methods are CNC Machining and Injection molding.

Both methods are great for various plastic parts. However, they come with numerous advantages and disadvantages. This guide explores CNC machining vs. Injection Molding to determine which one is better for product development.

What is CNC Machining?

CNC Machining or Computer Numerical Control is a process that begins with a block of the preferred material and then takes away some material layers.

Through computer control cuts, materials are removed from a solid block, a layer at a time. The procedure allows many different materials to be used with very few limitations.

Advantages of CNC Machining

- With CNC Machining, one person can supervise several CNC machines. This is because once they are programmed, they can function independently. All you need is to replace cutting tools regularly.

- The software design of the CNC machine tools can be manufactured many times, and every manufactured item is identical.

- With CNC Machining, it is possible to modify the size and shape of the product. All you need is to modify the processing program.

- CNC machines can be used during the day and at night constantly all through the year.

- It can process even the most unobservable parts.

- CNC Machining is the best option for high production efficiency.

Disadvantages of CNC Machining

- Investment in a CNC machine can lead to unemployment. This is because very few people are needed to operate the machine.

- Machine tools and maintenance cost is high. Hence, higher production costs.

What is Injection Molding?

Unlike CNC Machining, Injection Molding Machine involves inserting a material into a mold. The stock material is melted and then forced into a mold at high pressure.

The part is then let to cool for some time. Once it cools, it is ejected from the mold. You need to repeat the procedure for the next part, and so on.

Advantages of Injection Molding

- A person can manage more than one injection machine.

- It is possible to shorten the molding cycle by condensing and solidifying the melt.

- Production efficiency is very high. This is because sets of molds can have hundreds of cavities.

- With Injection molding, it is possible to create a plastic part with a unique shape.

- The waste generated during molding can be reused. Hence, the waste of raw materials in injection molding is very minimal.

Disadvantages of Injection Molding

- The quality of molded products is affected by several factors. Hence, the technical requirement is very high.

- Even though the injection molding process is not long, the cycle from design to manufacture and the mold trial is a bit long.

- It Might not be suitable for producing small-volume plastic parts since the price of the injection molding machine is very high.

- It is challenging to form a plastic part with a thick wall due to the limitations of cooling conditions.

Tips you should consider before choosing CNC Machining or Injection Molding

.

Material

Many people consider CNC Machining because it provides a selection of materials that you can use to make various parts. Moreover, harder plastics are easier to machine than softer materials.

But with injection molding, the material variety is limited. Nevertheless, there are several materials that you cannot machine but can mold.

Design

When designing your product, you need to understand that it is difficult to change or modify molds in designs. Also, designing parts for machining is different from those for molding.

With CNC Machining, design is flexible. It is possible to make numerous features with machining but a challenge with molding. On the other hand, injection molding is for deep features that might be expensive or hard with machining.

Cost

With CNC Machining, each product has its own cost and time. So, if you are producing a few items, CNC Machining is the most effective. But if you are going to increase the quantity, the cost of production will go up.

So, if you have several products to produce, the best option might be Injection Molding. Nevertheless, the cost of making a mold is high. So, if you are producing limited parts, CNC Molding is more cost-effective than Injection Molding.

Surface Finish

When it comes to surface finish, the benefit goes to CNC Machining. It is possible to obtain a better surface finish when using a machine. With Injection molding, molds can last longer with minimal wear.

Volume

CNC Machining is cheaper when producing a few parts, depending on the volume. With larger volumes, there is no extra benefit. On the other hand, the cost per part is significantly cheaper than machine parts.

Final Word

When choosing between CNC Machining and Injection Molding, you must consider the above factors. Moreover, make sure you double-check your budget, design, surface finish, time, and the volume of the product.

Remember that CNC processing offers more materials for manufacturing than Injection Molding. On the other hand, there is more waste in CNC machines than in injection molding.