Today we will discuss about servomotor and its types. After reading this article you can find answer of following question-

- What is Servomotor?

- Types of Servomotor

- What are Main Parts of Servomotor?

Hope you enjoy this article.

What is Servomotor,its Parts and Types?

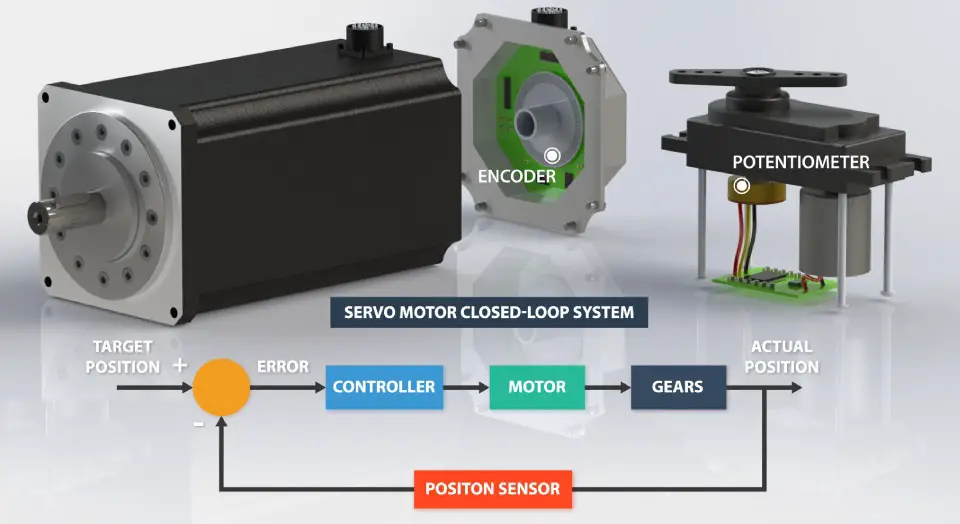

Servo implies an error sensing feedback control mechanism which is utilized to correct the performance of a system, which a general motor does not have. Servomotor makes use of a regular motor and pair of the sensor for position feedback. This motor can easily rotate in both direction and also hold the position at any angle with the use of control mechanism. This motor is basically used in automation industries where we want desired motion by pre-programmed input.

Now one question arise in mind that how a simple motor perform at that accuracy level. The answer hidden in a sophisticated controller, usually a devoted module designs particularly for use with the servomotor. This servo circuit is assembled right inside the motor chamber and has a shaft which can be positioned, that is usually fitted with gear mechanisms. This motor is controlled with an electric signal that determines the amount of movement of the shaft. It is the closed loop mechanism that uses position feedback in order to control its rotation speed and position.

A servomotor consist four main parts.

- Induction Motor

- Gear assembly

- Position Sensor

- Controller

There are two types of servomotor

- AC servomotor.

- DC servomotor.

AC servomotor:

It is basically two-phase squirrel cage induction motor and is used for low power application. In this, the reference input at which the motor shaft has to maintain at a certain position is given to the rotor of the synchronic generator as mechanical input.

The rotor is made up of laminated steel and bars of conducting material such as aluminium are buried in the rotor which is short-circuited at both ends. The stator is too made of aluminium steel with properly designed slots, and it is connected to the power supply. The power supply generates a rotating magnetic field. When the rotor is connected to the power supply, voltage is induced in a bar located in the rotor which causes the current flow through them. The electromotive torque is developed which accelerates the rotor. The AC servomotor is always rotating at the speed lower than the synchronous speed.

DC servomotor:

It is consists of a DC motor, gear system, position sensor and a control circuit and a gear assembly. A DC reference voltage is set to the value corresponding to the required output. This voltage varies through the voltage converter or through timers depending on the control circuits. The dial on the potentiometer produces a corresponding voltage which is then applied as one of the inputs to the error amplifier.

In digital controls, the micro controller is used for generating the pulse width modulation (PWM) pulses in term of duty cycles to produce more accurate control signals.

It has minimum and maximum pulses and a repetition rate. The servo meter turns 90 degrees in either direction for the total 180-degree movement.

The feedback signal corresponding to the present position of the load is obtained by using the position sensor. This sensor is normally a potentiometer which produces the voltage corresponding to the absolute angles of the motor shaft through the gear mechanisms. The feedback voltage value is applied at the input of the error amplifier.

The error amplifier is the negative feedback amplifier and reduces the difference between its inputs.

The error voltage is applied to the armature of the motor. If the errors are more, then the more outputs are applied to the motor armature. The amplifier amplifies the error voltage and correspondingly power the armature. The motor rotates until the error becomes zero.

Advantages

- Easily available in all sizes.

- Work well for velocity control

- Gives high intermittent torque.

- High efficiency.

- The Operation is possible even at high speed.

- Vibration free operations.

Disadvantages

- Not suitable in vacuum.

- More expensive than stepper motor.

- Tuning is required to stabilize feedback loop.

- The Design is complex as the micro controller, microprocessor is used.

- The Motor cannot sustain overload.

Applications

- Robotics to actuate the robot arms

- Conveyor belts to carrying the products along to various stages.

- Camera auto focus to sharpen out of focus images.

- Automatic door opener.

- Antenna positioning.

- CNC Machining

This is all about the servomotor. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more informative articles. Thanks for reading it.