Hello friends,

In my previous articles we have discussed about drum brake which is a most common braking system but now it is replaced by another system of braking is known as Disc Brake. Disc brake is a newer and most effective braking system due to its easy operation, high heat decapitation, fast operation etc. These days disc brakes are commonly use in front when and most of automobiles use it in rear wheels.

In this article, we will discuss about its construction features, working along with its advantages and disadvantages.

Disc Brake:

Construction:

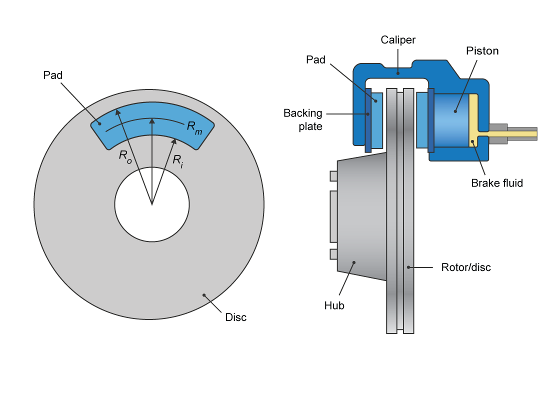

This braking system consists following parts.

Disc:

This brake consist a disc. A disc is a friction surface which is attached to the wheel and rotates along with it. When the friction force applied on the disc, it slow down the wheel thus vehicle. Discs are generally made by ceramics or carbon fiber due to their antiwear quality and also have light weight.

There are two types of disc available in market one is known ass solid type and other one is known as ventilated type.

Caliper:

It is assemble of pistons, brake pads, actuating mechanism etc. It is connected to some stationary part of the vehicle like axle casing or stub axle in two parts. Each part situated as one side of the disc.

Piston:

Piston use to apply brake when required. This piston is operated hydraulically by some mechanism. It is commonly made by aluminum or chrome plated iron.

Brake Pads:

It is friction lining material attached to the front of the piston. When the brakes are in engaged position, friction generates between the disc and brake pads which slow down the vehicle or tends to stop.

Working:

Disc brake consist a cast iron disc bolted to the wheel hub and a stationary housing called caliper. The caliper contains single piston. Some high performance brakes may have as many as eight pistons. In between each piston and disc, there is a friction pad held in position. This piston is operated by fluid. When the brakes are applied, hydraulically actuated pistons move the friction pads which make contact with the disc, which further apply equal and opposite braking force. This will slow down the disc thus wheel.

When the brake is released, the spring mechanism acts to retract the piston and friction pads away from the disc.

Advantages:

- High heat decapitation quality.

- Lighter in weight.

- Provide uniform pressure distribution.

- Uniform wear of friction pads.

- Easy maintenance.

- Self-adjusting brake

- High anti fade quality.

- Simple in design

Disadvantages:

- High cost compare to drum brake.

- Higher pedal pressure required.

This is all basic of construction and working of disc brake. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more informative articles. Thanks for reading it.