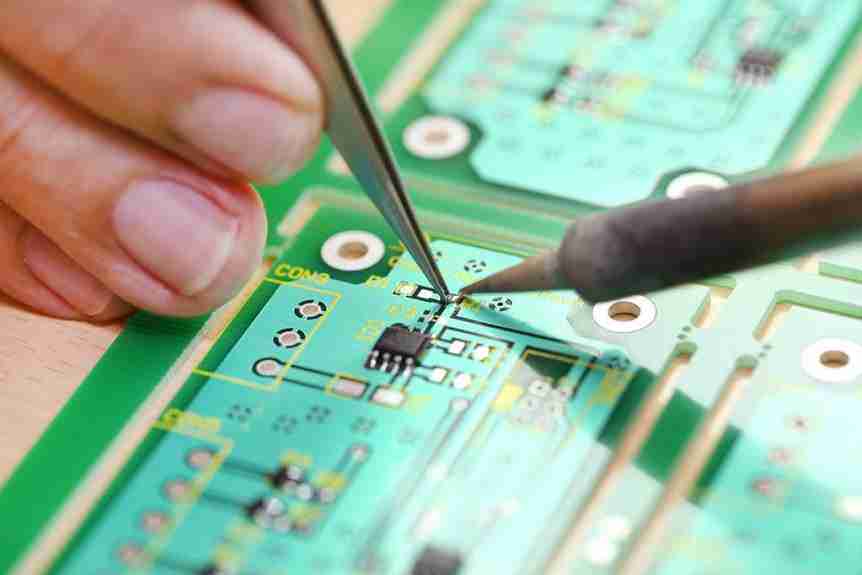

How Automated Optical Inspection Enhances PCB Assembly Quality

In an era where electronic devices are becoming smaller, more complex, and more ubiquitous, ensuring the quality of Printed Circuit Board (PCB) assemblies is paramount. One technology that is revolutionizing quality assurance in PCB assembly is Automated Optical Inspection (AOI). This article explores how AOI enhances PCB assembly quality and the crucial role it plays …

How Automated Optical Inspection Enhances PCB Assembly Quality Read More »