Laser Beam Machining : :Principle, Working, Equipment’s, Application, Advantages and Disadvantages

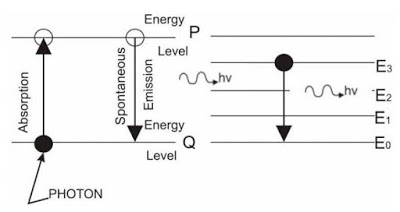

Today we will learn about laser beam machining principle, working, equipment’s, application, advantages and disadvantages with its diagram. Laser beam machining is a thermal machining process which uses laser beam to produce heat. In this machining process metal is removed by melting and vaporization of metal particle from surface of work piece. It is a …