A centrifugal pump is the simplest machine which is used in various industries as well as in many daily applications to transfer fluid from lower head to higher head. In 1475, Italian engineer Francesco di Giorgio Martini designated mud lifting machine as a centrifugal pump. But actual centrifugal pumps were not discovered until 17th century. Then Denis Papin created one centrifugal pump by using straight vanes. Later, in 1851 British inventor John Appold designed curve vane.

Centrifugal pumps are mostly used in chemical industries for easily transfer viscous fluids. Also, it is less expensive than other pumping devices. In short, it is an excellent machine with efficient working in variety of applications. Let us learn on which principles it works, working process, its components, advantages and finally applications.

Centrifugal Pump:

Principle:

This pump works on basic principle of change in angular momentum. It state that the change in the angular momentum of a rotating particle is equal to the applied force. It means when a certain amount of liquid is rotated with the help of external agency means turbines or electric motor or external force, a centrifugal force acts on it which further turns into pressure. In addition to, this as liquid passes through revolving wheel then there is change in angular momentum of rotating wheel or impeller which generates more amount of pressure. In short, in a centrifugal pump kinetic energy of impeller is converted into pressure energy of fluid which is used to raise up it to certain height. Due to centrifugal force acting on water or fluid, it is lifted up to particular height. So these pump is called as centrifugal pump.

Main Parts:

Centrifugal pump consists of two types of parts:

1.) Rotating components:

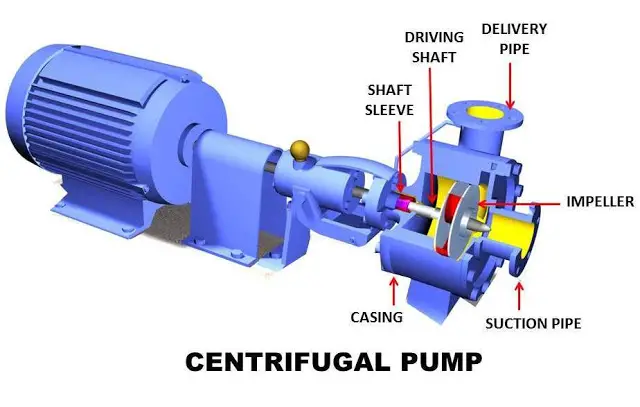

It consists of a shaft and an impeller

A.) Impeller:

It is the main part of centrifugal pump. It provides centrifugal acceleration to the liquid. Impeller has again its sub-types.

a.) Open impeller:

This impeller is without crown and base plate. This type of impeller is useful in removing liquid containing solid particles such as water containing sand, paper pulp etc.

b.) Closed impeller:

Closed impeller has vanes which contain cover plates on both sides. It is mostly used in obtaining pure water.

c.) Semi-open impeller:

It has only base plate and don’t has any crown plate. It is comfortable with fluid containing charged debris.

B.) Shaft:

It is used to rotate the impeller. It is designed to transmit torque encountered while starting and operating time of impellers and other rotating components.

C.) Shaft sleeve:

Sleeves prevent centrifugal pump shaft from corrosion and leakage points. It should be taken care that sleeves should be sealed at one end.

2.) Stationary components

It consist of casing, bearings, suction pipe.

A.) Casings:

These casings are similar to the casings of a turbine. There are two types of casings:

a.) Volute casings:

Volute is the funnel of increasing area and generally curve in shape. As cross sectional area of funnel decreases velocity of liquid decreases with increasing pressure. These are created to have a higher head. To balance the pressure on shaft of centrifugal pump is the focus behind developing volute casings.

b.) Circular or Vortex casings:

These have vanes which surrounds impeller periphery and convert kinetic energy into pressure energy.

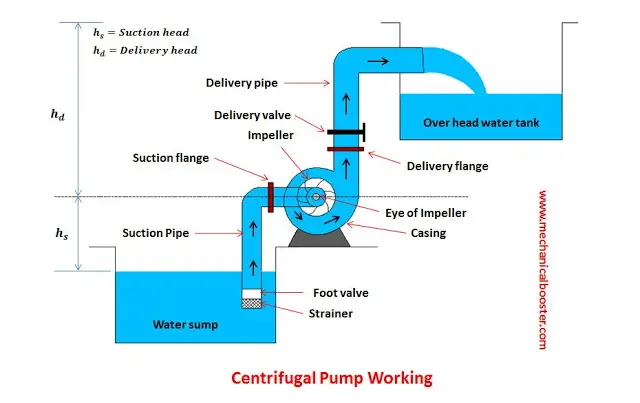

B.) Suction pipe:

The lower end of a suction pipe is dipped in water which is to be lifted up and the other end is connected to the inlet of centrifugal pump. Strainer and foot valve present at the lower end of the suction pipe help to remove waste material from water such as leaves, sand and to allow the flow of water only in upward direction, respectively.

Types:

Following is the classification of centrifugal pump.

A.) According to the type of casing:

Turbine pump:

It consists of vanes which surround impeller on a diffuser ring. These vanes and diffuser ring both are in stable position and distance between vanes provide a direction to the flow of liquid. Fluid leaving impeller flows through these empty spaces with high pressure. After leaving vanes the fluid goes into casings which may be circular, concentric or volute shape. It has been founded that we can convert 75% of kinetic energy into pressure energy. Disadvantage of these pumps is that they are very expensive.

Volute pump:

In this pump, impeller is covered by volute chamber. These volute casing may be created in such a way that having equal velocities of liquid leaving impeller and entering the pump. If it is designed as mentioned above then there is very less loss of energy but kinetic energy cannot be converted into more useful potential energy.

B.) According to the impeller number per shaft:

Centrifugal pumps may be classified as multi-stage and single-stage depending upon the number of impellers. Multi-stage pump has two or more series joined impellers enclosed in same casing. Single-stage pump has only one impeller mounted on the shaft.

C.) According to the direction of liquid flow through impeller:

These pumps may be classified on the basis of direction of flow of liquid through the impeller as axial flow pump, mixed flow pump and radial flow pump.

D.) According to the number of entries to the impeller:

E.) According to the configuration of shaft:

Working:

Before discuss about its working you should learn about what is priming and why it is essential for proper working of centrifugal pump.

Priming:

Priming is the most basic and first step in the working of centrifugal pump. The process of filling the casing, suction pipe and delivery pipe upto the delivery valve before starting the pump is known as priming. In order to remove the air gap present in pump, it is filled by liquid. Pressure developed inside the pump is directly proportional to the density of liquid in it. If there is air in pump and an impeller is allowed to rotate then pressure energy cannot be developed as density of fluid is less due to presence of air. So it is very important to prime a centrifugal pump carefully.

Its working can be summarized into following points.

|

| Image Source |

- First priming is done before starting the pump. Delivery valve is still kept closed.

- Now the motor starts. The rotation of impeller in the casing full of liquid accelerates liquid and there is generation of powerful centrifugal force which results in enhancement in liquid pressure.

- This increase in pressure is directly proportional to the square of angular velocity and distance of point from the axis.

- Therefore, if the impeller rotates with faster speed, there is greater amount of production of required pressure energy.

- Now the delivery valve open and allow liquid to flow at desired location.

Liquid comes out of impeller with high velocity. This increasing kinetic energy due to increased velocity can be wasted in eddies which result in decreasing the efficiency of pump. So safety should be taken to reduce this speed as that of lower velocity of delivery pipe.

Advantages:

- Centrifugal pumps don’t have any leakage issue.

- They are able to pump hazardous as well as sensitive fluids.

- There is also no problem of heat transfer as the space between the motor and chamber is sufficiently large.

- There is no loss of power due to friction and they are very simple in structure and easy in handling.

Disadvantages:

- Magnetic resonance in centrifugal pump results in small loss of energy.

- The risk of the clogging of pipe may arise due to particle attractive nature of magnetic drive.

- Vibrations due to surrounding atmosphere can damage these pumps.

- The risk of cavitations is always there.

Applications:

- These pumps are used in buildings for pumping the regular water.

- They are used in the fire protection related services.

- Centrifugal pumps are used to transfer lactose and other drugs in pharmaceutical industry.

- They are also used in coolant recirculation, refrigerants.

- These pumps are used in sprinkling, irrigation, drainage.

This is all about centrifugal pump principle, construction, working, types, advantages, disadvantages with its application. if you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more informative articles.

I am a computer professional . I do little agricultural activities too and for that I am using an ordinary pump set coupled with AC motor. It is only 1hp capacity. I do not have an over head tank . I distribute water by taking 4 outlets at different places. Mostly I need to water only trees and as such no problem with the pressure of outlet. IMy doubt is can I start the pump with outlet closed. I am told in certain pumps a relief valve is required to avoid bursting of pipe in case pump is started with delays very pipe closed. Kindly guide me in this aspect! Thanks . PRM nair.

Thanks for sharing this informative article on Centrifugal Pumps

Since I’m not familiar with centrifugal pumps for work, I chose to learn more about them after hearing about them from my brother. It’s a good thing I stumbled upon your blog because you talked about how they’re utilized in the pharmaceutical sector to transport lactose and other medications, as well as in services relating to fire safety. Making sure you have a high-quality one is essential because it appears to be important to several sectors. Thank you for sharing, I will definitely let him know about this!