Accuracy of any machine part or a product is most common concern for engineers. They continuously works for develop those technologies which provide a highly accurate part with minimum tolerance. Honing is one of these processes which is used for provide better surface finish and highly accurate work piece. It is a finishing or we can say super-finishing process used for finishing round holes by means of an abrasive material.

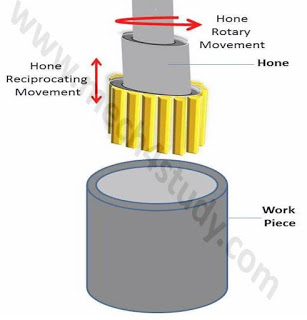

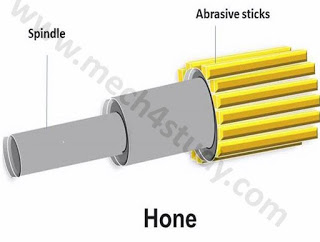

This process uses a cylindrical mandrel dressed with an abrasive material like aluminium oxide, silicon carbide, diamond etc. This tool is called hone. This tool carried out a combined rotary and reciprocating motion to remove material at whole length of stationary work piece. The tool rotates at its own axis and reciprocates in the cylindrical hole to cover whole length of work piece. Mainly honing is considered as follow up process after drilling or boring. Sometimes it is used for finishing external surfaces.

Learn more about what is honing its process parameters, types along with its advantages in this article.

What is honing?

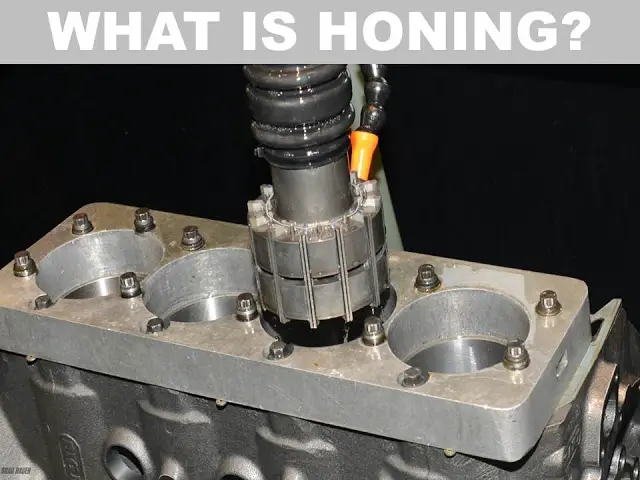

Honing can be considered as a machining process because it involves metal removal in form of microchips. The word “Honing” is developed by the word “Hone”. Hone is used for a cylindrical tool dressed with some abrasive material. This abrasive material is used in the form of sticks which are mounted on the mandrel. However nowadays diamond and carbon boron nitrite grits are used for complete the operation in just one stroke. This process is used for achieve accurate dimension of cylindrical holes. It is best suited for finishing engine cylinder. Sometimes It is used for finishing gear where tool made with plastic impregnated with abrasive.

In honing process a well-dressed (with abrasive particles) cylindrical tool rotates at its own axis. The tool diameter is almost equal to the work piece internal diameter. This tool rotates at its own axis and also reciprocates which allows to remove material in form of microchips. It can achieve tolerance of about 0.25 – 1.5 micron. This cutting form a cross lay hatched pattern at work piece.

|

| Honing Process |

The accuracy and surface finish of hole is mainly depends on various process parameter which are describe below.

Process Parameters:

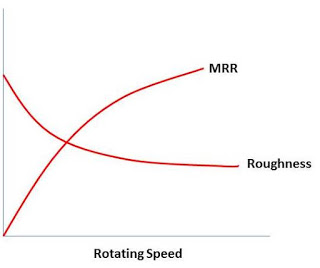

RPM of tool:

If the tool speed increases, it increases metal removal rate and decreases surface roughness.

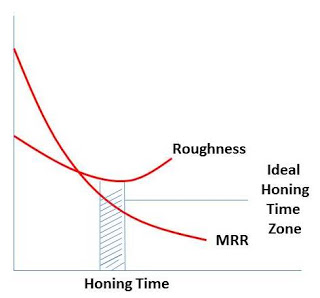

Honing time:

If we increase honing time it will decrease surface roughness at some extent and then starts increases it. It is so selected which gives minimum surface roughness with maximum metal removal rate.

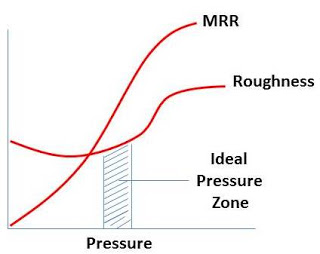

Honing stick pressure:

The change in metal removal rate and surface roughness with the change in unit pressure is shown in the graph. The honing stick pressure is so selected as to get minimum roughness with highest metal removal rate.

Stroke Length:

The stroke length should be as enough which can cover the whole working length.

Types:

Honing can be classified into two types.

Manual Honing:

In this type of honing the hone rotate continuously and the work piece is move front and back manually. This process is rarely used now days

Machine Honing:

The honing process in which the hone performs combined rotary and reciprocating motion and there is less manual interaction called machine honing. According to the type of machine this process can be classified into two types

1. Vertical honing

2. Horizontal honing

Advantages:

- Less complex or low cost fixtures.

- It is highly accurate.

- It can be used for both long and short bores.

- It maintains original bore centerline.

- Any material can be finished regardless its hardness.

This is all about honing process, its working, types, process parameters and its advantages. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social network. Subscribe our website for more informative articles. Thanks for reading it.

VERY APT AND TO THE POINT INFO OF HONING PROCESS

THANK YOU

How solve top to bottom tapper problem and over size problem at the middle of the component

i have some questions releated to superfinishing process can u explain any 2 components process how is it superfinished

A long way, you can finish step by step, and then you can’t reach without a foot

Can be used coolant in this process or not????