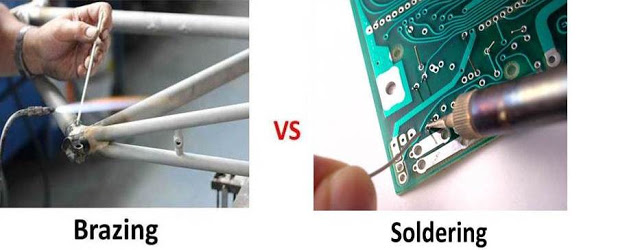

Soldering and brazing both are metal joining process used in different joining conditions. These processes are more confusing to differentiate because both process use filler material and done below critical temperature.

Today I am going to tell you difference between soldering and brazing so you can understand these processes clearly. The basic and main difference between soldering and brazing is that soldering is used to make a electrically strong joint between metals which can withstand with all electric loads and brazing is used to make a mechanical strong joint which can withstand with all mechanic loads and stresses. These processes can be differentiating in following aspects.

Today I am going to tell you difference between soldering and brazing so you can understand these processes clearly. The basic and main difference between soldering and brazing is that soldering is used to make a electrically strong joint between metals which can withstand with all electric loads and brazing is used to make a mechanical strong joint which can withstand with all mechanic loads and stresses. These processes can be differentiating in following aspects.

|

S. No.

|

Soldering

|

Brazing

|

|

1.

|

It is used in electrical industries to joint capacitor, resistor, wire etc. to the electronic plate.

|

It is used to mechanical industries to joint different metals.

|

|

2.

|

Soldering is done at temperature below 200 C.

|

Brazing is done at temperature above 450C but below the critical temperature of metal.

|

|

3.

|

These joints are weaker than brazing joints.

|

It forms stronger joint.

|

|

4.

|

In soldering an alloy of lead and tin is used known as solder.

|

In brazing an alloy of copper and zinc is used as filler metal.

|

|

5.

|

It does not need a special training to soldering.

|

It needs special trading.

|

|

6.

|

It is a cheaper process.

|

It is a costly process.

|

|

7.

|

Soldering does not need to preheat of base metal.

|

This process needs preheating of base metal.

|

|

8.

|

It is used to joint electronics component.

|

It is used in automotive industries and pipe fitting.

|

|

9.

|

This process is very flexible and easy to automate.

|

It is not so easy for automation except automation is done at automotive industries.

|

These are the difference between soldering and brazing. If you have any query asks by comment. Thanks for reading it.

Thank you so much. Cheers!

Awesome

Thank you for the information friend!

provide it by definition for both and using of filler materials

Thank you very much 🙂

thank 🙂

Useful

Thank you for creating this site. Very helpful

Is Brazing is soldering or welding?

What will happen if soldering is used in automotive industries instead of brazing???

I am happy and hope this article will help me in tomorrow’s exam.

I thanking you alot ,for this deep knowledge.

Thank you so much